Using

Allen-Bradley Controllers via Message Block

Most Allen-Bradley PLCs and PC-based controllers

(ControlLogix, CompactLogix, SLC5/05, PLC-5, SoftLogix, etc.) support

serial RS-232 and Ethernet communications, either built-in or through

an add-on module.

This topic describes how to communicate with

the RMC from the Allen-Bradley PLCs via the Message (MSG) block. For information

on using EtherNet/IP I/O with the Logix PLCs, see the Using

Allen-Bradley Controllers via EtherNet/IP topic. For details on using

Allen-Bradley's RSView operator interface with the RMC, see the RSView

with the RMC topic.

The Allen-Bradley PLCs can read or write from

registers in compatible remote devices such as other Allen-Bradley PLCs

or the RMC. The RMC contains floating point (F) files, all of which are

accessible over serial or Ethernet from the Allen-Bradley PLCs. See DF1 Addressing

for details on finding those registers and their addresses.

If you need help setting up your Ethernet

network, either consult your network administrator, or for simple stand-alone

networks, see Setting

Up a Standalone TCP/IP Network.

For setting up the RMC75S serial settings,

see the Configuring

Serial Communications topic. For setting up the RMC75E,RMC150E, or

RMC200 Ethernet, see the RMC

Ethernet Setup topic.

Example Programs

Delta provides example PLC programs to help

you quickly set up the communications between your PLC and the RMC. See

the downloads

section of Delta's website at https://deltamotion.com.

Message (MSG) Block

The Allen Bradley PLCs and controllers listed

above all use the same ladder logic block to communicate over Ethernet:

the Message (MSG) block. This block takes a number of parameters, which

are briefly described below. For a complete description of the parameters,

refer to Allen-Bradley's Instruction Set Reference Manual for the appropriate

PLC.

MSG Parameters

The MSG block parameters differ slightly depending

on the controller and programming software. The parameters used by RSLogix

5 version 3.2.0.0, RSLogix 500 version 6.30.00, and RSLogix 5000 version

17.00.00 for the PLC-5, SLC 5/05, ControlLogix and CompactLogix controllers

respectively are described below. The SoftLogix 5 parameters are similar.

ControlLogix and CompactLogix MSG Block

Parameters

ControlLogix and CompactLogix MSG Block

Parameters

The ControlLogix or CompactLogix MSG block is displayed as follows. More detailed information on the MSG block is available in Allen Bradley publication 1756-RM003L-EN-P, Logix5000 Controllers General Instructions.

The Message Control portion of the MSG requires a tag.

To create a tag:

-

Right-click the "?" and choose NewTag.

-

Type a name in the Name field.

-

Make sure the Data Type is MESSAGE.

-

Click Configure. The Message Configuration dialog will open.

-

2, station address

where station address is the node address of the RMC. For example, if the node address is 3, the path is:

2, 3

Note:

The "2" is the port number for the serial port on the ControlLogix CPU.

SLC 5/05 MSG Block Parameters

SLC 5/05 MSG Block Parameters

The SLC 5/05 MSG block is displayed as the following:

|

Parameter

|

Description

|

|

Type

|

This

parameter is always set to Peer-To-Peer for serial or Ethernet

communication channels.

|

|

Read/Write

|

This

parameter should be set to Read

to read registers from the RMC and to Write

to write registers to the RMC.

|

|

Target Device

|

This

should be set to 500CPU

for communicating with the RMC.

|

|

Local/Remote

|

This

parameter has possible values of Local and Remote. It should

be set to Local for

communicating with the RMC.

|

|

Control Block

|

This parameter points to a block

of integer-file registers (51 registers for Ethernet, 12 for

serial). Set this to a block of registers, and then

use the Setup Screen option in the MSG ladder logic block

to modify those register values:

MultiHop: This parameter

should be set to No.

-

Local/Remote and Bridge Parameters:

In most applications these will be set to Local and there

will be no bridge parameters. If you are using a bridge then

these parameters will need to be used. However, this is beyond

the scope of RMC documentation. Refer to your Allen-Bradley

documentation for instructions on using these fields.

|

|

|

|

Note:

For the SLC505, if the start of communications with the RMC exhibits several minutes of delay after power-up, it is because your SLC processor and/or firmware is old. Newer SLC processors do not have this problem.

PLC-5 MSG Block Parameters

PLC-5 MSG Block Parameters

The PLC-5 MSG block is displayed as follows:

The Control parameter points to a block of 51 N-file (integer) registers or two (2) MG-file (message) registers. Set this to an unused block of registers, and then use the Setup Screen option in the MSG ladder logic block to modify those register values:

|

Register

|

Description

|

|

This PLC-5

|

This section holds parameters

for the PLC-5:

-

Communication Command:

From this drop-down list, select PLC-5 Typed Read to read

values from the RMC, or PLC-5 Typed Write to write values

to the RMC.

-

Data Table Address:

Enter the address of the first Allen-Bradley PLC register

to read RMC registers into, or to write to RMC registers

from.

-

Size in Elements: Enter

the number of RMC registers to read or write in this field.

Transfers are limited to 1000 bytes for PLC-5 Typed Reads

and Writes. Therefore, this limit is 500 integers, 250

floats, etc.

-

Port Number: Set this

to the Ethernet channel number. For the PLC-5, this should

be channel #2.

|

|

Target Device

|

This section holds parameters

for the target device:

MultiHop: This parameter

should be set to No.

Ethernet (IP) address: Set

this to the IP address of the RMC you wish to communicate

with.

Local Node Addr (dec): Enter

the node address of this RMC. The node address of the RMC

is set up in the Serial

Port Settings Page. The node address entered on that screen

is in decimal, so it is recommended that you enter the same

number in the dec field.

|

MicroLogix

MSG Parameters

MicroLogix

MSG Parameters

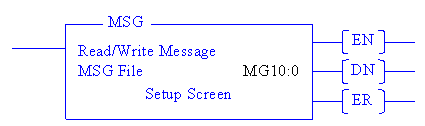

The MicroLogix MSG block is displayed as follows:

Serial Communications:

To edit the parameters of the message block, select the MSG block, enter an unused MSG file in the MSG File parameter, and double-click Setup Screen. This brings up a dialog with the following options:

This Controller: This section holds parameters for the MicroLogix.

Communication Command: From this drop-down list, select PLC-5 Typed Read to read values from the RMC, or PLC-5 Typed Write to write values to the RMC. The SLC Typed Read or Write will also work, but is limited to 58 registers.

Data Table Address: Enter the address of the first Allen-Bradley PLC register to read RMC registers into, or to write to RMC registers from.

Size in Elements: Enter the number of RMC registers to read or write in this field. The MicroLogix can transfer 1 to 41 integers.

Channel: Set this to the channel number of the serial port you want to use. The MicroLogix 1500 LRP Series B can use either channel 0 or 1, but all other MicroLogix PLCs will always use channel 0.

Target Device: This section holds parameters for the target device.

Message Timeout: Indicate the number of seconds to wait for the RMC to respond before determining that the attempt failed. This can be set as low as a few seconds.

Data Table Address: Enter the address of the first RMC register to read or write in this field. See the Registers Maps topic for help on addresses.

Local Node Addr (dec): Enter the node address of this RMC. The node address of the RMC is set up in the Serial Port Settings Page. The node address entered on that screen is in decimal, so it is recommended that you enter the same number in the dec field.

Local/Remote and Bridge Parameters: In most applications these will be set to Local and there will be no bridge parameters. If you are using a bridge then these parameters will need to be used. However, this is beyond the scope of RMC documentation. Refer to your Allen-Bradley documentation for instructions on using these fields.

Ethernet Communications (MicroLogix 1100):

-

In the RSLogix project tree, in the Data Files, create a message File (MG) data file and a Routing Information (RI) data file.

-

Add the MSG block to the ladder logic. Select the MSG block, enter the an address in the Message data file you just created (e.g MG9:0), and double-click Setup Screen.

This brings up a dialog with a General tab with the following options:

This Controller: This section holds parameters for the MicroLogix.

Channel: To use Ethernet on the MicroLogix 1100, choose 1 (integral).

Communication Command: This parameter can be set to PLC5 Read, PLC5 Write, 500CPU Read, or 500CPU Write. The type of PLC selected is not important, but the Read or Write determines whether you will read registers from the RMC or write registers into the RMC.

Data Table Address: Enter the address of the first Allen-Bradley PLC register to read RMC registers into, or to write to RMC registers from.

Size in Elements: Enter the number of RMC registers to read or write in this field.

Target Device: This section holds parameters for the target device.

Message Timeout: Indicate the number of seconds to wait for the RMC to respond before determining that the attempt failed. This can be set as low as a few seconds.

Data Table Address: Enter the address of the first RMC register to read or write in this field. See the Registers Maps topic for help on addresses.

Local / Remote: Choose Local.

Routing Information File (RI): Enter the address in the Routing Information File that you intend to use (e.g. RI10:0).

-

On the Multi-hop tab, in the To Address box, enter the IP address of the target RMC. For example, 192.168.0.219.

Using the MSG Block in Ladder Logic

The Allen-Bradley MSG block may take multiple

ladder scans to complete. Therefore, it is important to enable the MSG

block for the correct amount of time. Specifically, the MSG block must

be energized until the message control's enable (EN) bit turns on. Following

the ladder samples to ensure proper functionality:

Read or Write Continuously

Using the Examine

If Open instruction as shown below fulfills two requirements of continuous

MSG transactions. First, it will keep the block energized until the EN

turns on, and second, it de-energizes the MSG block once the transactions

is started so that when the transaction is completed (EN goes low again),

the MSG block sees a rising edge on its input, thus repeating the transaction:

Read or Write Once

This sample takes

care to keep the MSG block energized until the MSG block starts, as indicated

by the enable (EN) bit turning on. Once this happens, the application-controlled

TriggerOnce coil is turned off. The message control's Done (DN) or Error

(ER) bits can be used to process the results of the transaction.

Reading DWORDs from the RMC

All items in the RMC have F-file addresses.

Allen-Bradley defines F file data as 32-floating point values. All the

RMC registers have F-file addresses, even if they are DWORDs or DINTs.

For example, the Status Bits and Error Bits in the RMC are DWORDS. To

read these values, read them using their F addresses as given in the RMC.

Then, in the PLC, use the COP instruction (RSLogix5000), or CPW instruction

(RSlogix500) to copy the data to a register or tag of the correct data

type, for example, an N register, L register, or DINT tag. The COP instruction

preserves all the bits correctly, and the resulting values will be correct.

If the PLC must write a DINT or DWORD in the

RMC, use a similar method.

See Also

Ethernet Overview

| RMC75

Register Map | RMC150

Register Map | RSView with the RMC

Send comments on this topic.

Copyright © 2025 Delta Computer Systems, Inc. dba Delta Motion

![]() ControlLogix and CompactLogix MSG Block

Parameters

ControlLogix and CompactLogix MSG Block

Parameters