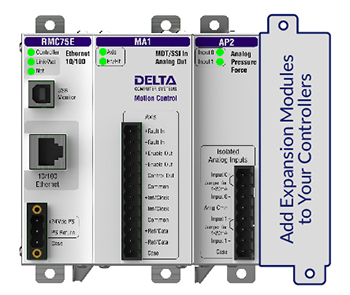

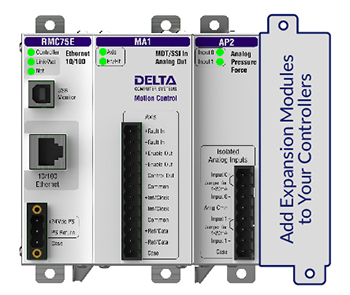

The RMC70 consists of a factory-configured Base Module containing the CPU Module (which includes communications) and a one- or two-axis Axis Module.

RMC70 I/O Module Details

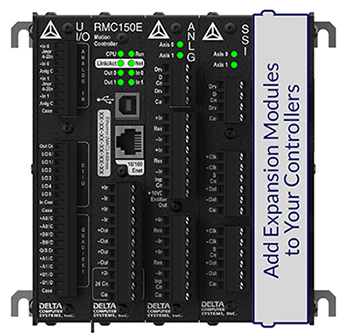

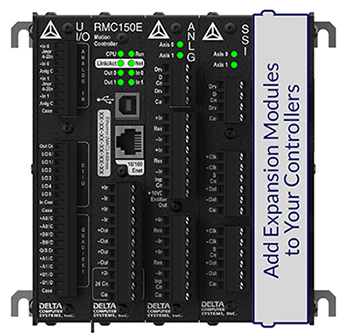

The RMC150 is available in 3-, 4-, 5- and 6-slot factory configurable packages. The first slot can contain only certain modules. The second slot contains CPU module. The additional 1-4 slots can contain any combination of axis modules (each handling 2 axes) or DI/O or analog inputs. Dual-loop position-pressure or position-force control is added by specifying RMC151 in the part number.

RMC150 I/O Module Details

The RMC200 is available in Lite and Standard configurations. Both configurations consist of a base and user-installable modules.

The RMC200 Lite uses special base modules, B5L and B7L, and a CPU with integrated power supply and shares all other modules with the standard RMC200.

Available Standard bases are B5, B7, B11, and B15. The first slot for Standard bases contains the power supply; the second slot contains the CPU module. For both Lite and Standard bases, the third slot may contain the optional EtherCAT MainDevice Communications module. Also for either of the bases, with or without the EtherCAT module, the additional slots can contain any combination of I/O modules. The dual-loop position-pressure or position-force control requires purchasing enough Feature Key control loops to total 2 loops per dual-loop axis.

RMC200 I/O Module Details