The AA axis module can be wired to voltage or current feedback transducers. The AA module also a Fault input, Enable output, and a Control Output. If the AA module has two axes, each axis' pin-out is identical.

Use shielded twisted pairs for all connections to inputs and outputs. Route the transducer wiring separate from other wiring. You must provide the power supplies needed by your transducers. See Wiring Guidelines for general wiring information.

Wire clamp screws must be tightened to max 7 b-in (0.8Nm).

NOTE:

The example schematics do not include transducer pin numbers, color codes,

or power supply requirements, since these vary between different transducers.

To determine your power supply needs and connector pin-outs or cable

color codes, consult your transducer manufacturer's documentation.

NOTE:

If the input is disconnected, input voltage will be pulled down ≤ -10V.

Pin-Out

|

Pin # |

AA1 Label |

AA2 Label |

Function |

|

1 |

+Fault In |

Flt In+ |

Fault Input |

|

2 |

-Fault In |

Flt In- |

|

|

3 |

+Enable Out |

En Out+ |

Enable Output |

|

4 |

-Enable Out |

En Out- |

|

|

5 |

Control Out |

Ctrl Out |

Control Output |

|

6 |

Common |

Cmn |

Common |

|

7 |

+Analog In |

An In+ |

+Analog Input |

|

8 |

Jumper for 4-20mA |

Jmpr for 4-20mA |

Jumper for 4-20mAfeedback |

|

9 |

-Analog In |

An In |

-Analog In |

|

10 |

Common |

Cmn |

Common |

|

11 |

+10Vdc Exciter Out |

+10Vdc Exciter |

+10Vdc output for potentiometers |

|

12 |

Case |

Case |

Connected to |

The commons are internally connected.

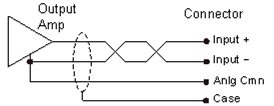

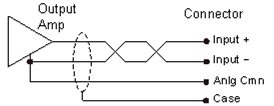

Voltage Feedback Transducers

Voltage feedback transducers can be connected directly to the Input + and Input - connections of the desired axis. The Cmn must be connected to the transducer, or the signal will not be read correctly! The following configuration is recommended:

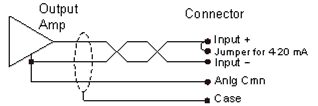

Current Feedback Transducers

Current feedback transducers are connected in the same way as voltage transducers except that a jumper must be inserted between the Input+ and Jumper for 4-20 mA pins. The label indicates where this jumper should be connected. This places a resistor internal to the RMC across the two inputs, thus converting the current to a voltage input. The wiring diagram below shows a suggested configuration.

The Cmn must be connected to the transducer, or the signal will not be read correctly!

2-Wire Current Transducer

Fault Input Wiring

The Fault input is compatible with signal levels ranging from 12V to 24V. The Fault Input draws 2.7mA maximum and turns on at 6V. The Fault input turns on when a current flows. The polarity of the voltage is unimportant. See the Fault Input topic for more details.

Fault input wiring diagrams:

|

Generic:

|

From Open Collector Output:

|

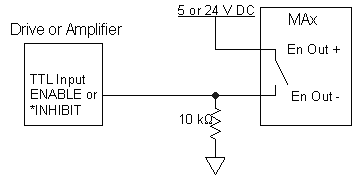

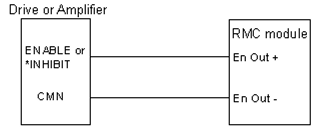

Enable Output Wiring

The Enable output is a solid state relay (SSR). When it is off, it has high impedance, and when on it has low impedance (10 Ω maximum). Because the Enable output is isolated, the user must power it externally. The maximum current and voltage for the Enable output is 100 mA and 30 V.

The Enable output has a + and - connection. Both lines must be connected for the output to function. Because both sides of the output are provided, the switches may be independently connected in a high side or low side configuration (that is, with the load (input) on the source or sinking side of the output). See the wiring diagrams below.

See the Enable Output topic for more details on the Enable Output.

To TTL input (high = enable):

To active low Enable input:

Using Outputs with Inductive Loads

External fuses should be used to protect the SSRs if there is a possibility of over-current. When switching inductive loads, it is important to place a diode or tranzorb across the load to protect the switch when transitioning from an “ON” to an “OFF” state. Otherwise, the collapsing magnetic field can cause a reverse voltage spike in excess of the 30 V rating of the SSR.

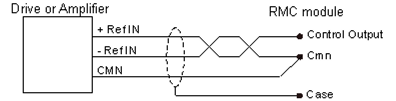

Control Output Wiring

The valve or motor drive connects to the following MAx pins:

|

Pin |

Function |

|

Control Output |

Control Output |

|

Cmn |

Control Output Common. Each axis has two Cmn pins. Either of the 2 pins may be used. |

See the Control Output topic for more details on the Control Output.

Note:

The Control Output polarity can be set with the Invert

Output Polarity parameter.

See Also

Copyright © 2025 Delta Computer Systems, Inc. dba Delta Motion