Pressure limit or force limit is a special type of pressure or force control, typically used on position-pressure or position-force axes. Pressure/Force Limit limits the Actual Pressure or Force during position or velocity motion. Pressure/Force Limit is useful in applications that require moving to a position while not exceeding a certain pressure or force during the move.

For example, consider a vehicle manufacturing application that presses a bearing into a steering knuckle. The bearing must be pressed to a final position, but the force during the move cannot exceed a certain value. Force limit is an excellent way to ensure that the move occurs as quickly as possible without damaging the bearing due to excessive force.

You can choose to apply Pressure/Force Limit in the positive or negative directions, or both. The Target Pressure/Force (or the negated Target Pressure/Force for the negative direction) is the value at which the Actual Pressure or Force will be limited. The axis position or velocity can be controlled normally as long as the Actual Pressure or Force does not approach the limit. As the Actual Pressure or Force approaches the threshold, the RMC will limit the motion so that the pressure/force limit is not exceeded. For more advanced details, see the Pressure/Force Limit Details topic.

Pressure/Force Limit cannot be used in Direct Output. To issue the Set Pressure/Force Limit Mode (40) command, the Direct Output Status bit must be off. To turn off the Direct Output Status bit, put the axis in Open Loop or Closed Loop control.

Note:

Pressure Limit mode may affect motion even when the Actual Pressure is well below the pressure limit. In order to achieve precise motion when pressure is not important, do not enable Pressure Limit mode. This may require the user to enable Pressure Limit mode only after the pressure has increased close to the point where the pressure is to be limited.

Pressure/Force Limit versus Control

Pressure/Force Limit differs from Pressure/Force Control. In Pressure/Force Control, the axis is controlling pressure or force independent of the position or velocity motion on the axis. In Pressure/Force Limit, the axis is performing position or velocity control while limiting the pressure or force.

Determining Whether Pressure/Force Limit is Required

Pressure/force Limit is usually more complicated than just pressure/force control. Therefore, you should not use pressure/force limit unless you need it.

If your application is only controlling pressure or force, then you probably do not need to use pressure or force limit.

If you want to transition between position and pressure or force control, and each control mode does not depend on the other, then you probably do not need pressure or force limit.

If you want to transition between position and pressure or force control, but you want to make sure the axis will not exceed a certain position while controlling pressure or force, you probably need pressure/force limit. However, you can use pressure or force control and monitor the other values from a user program to handle error conditions.

If you want to perform position or velocity motion, but limit the pressure or force during the motion, then you probably need pressure or force limit.

Using Pressure/Force Limit

Setting Up the Axis

Pressure/Force Limit is most useful on dual-loop axes, such as position-force. For details on setting up a position-pressure or position-force axis, see Position-Pressure and Position-Force Control. For details on setting up a pressure-only or force-only axes, see Controlling Only Pressure or Force.

Entering Pressure/Force Limit

Pressure/Force Limit requires first moving the axis in open loop or closed loop in order for the RMC to limit the pressure. The RMC will limit the Control Output to prevent the pressure/force from exceeding the Target Pressure/Force. Once the pressure/force is being limited the Target Pressure/Force can be changed using any of the pressure/force commands, except the commands that enter pressure/force control, because this will exit pressure/force limit

After setting up the axis for pressure or force control, follow the steps below to limit pressure/force. In order to limit the pressure or force, you must first tune it. See Tuning Overview topic for details.

Issue a pressure/force command (such as Ramp Pressure/Force (Linear) (42) ) to set the Command Pressure to the desired value.

Note:

After starting up the RMC, the Target Pressure/Force must be set up with a pressure/force command before issuing the Set Pressure/Force Limit Mode (40) command for the first time, or a Command Error will result.

You can move the axis in position or velocity control normally until you want to enter pressure/force limit.

When you wish to start limiting the pressure/force, issue the Set Pressure/Force Limit Mode (40) command to enable pressure/force limit. Pressure/Force Limit mode may affect normal closed-loop motion even when the pressure is very low. Therefore, if possible, do not enter Pressure/Force Limit until you need to.

Move the axis. When the motion begins to affect the pressure, the RMC will limit the motion such that the Actual Pressure/Force does not exceed the Command Pressure/Force. To make an axis go to a certain pressure/force, the axis must be commanded to move to a point at or beyond the point where the pressure/force limit is reached.

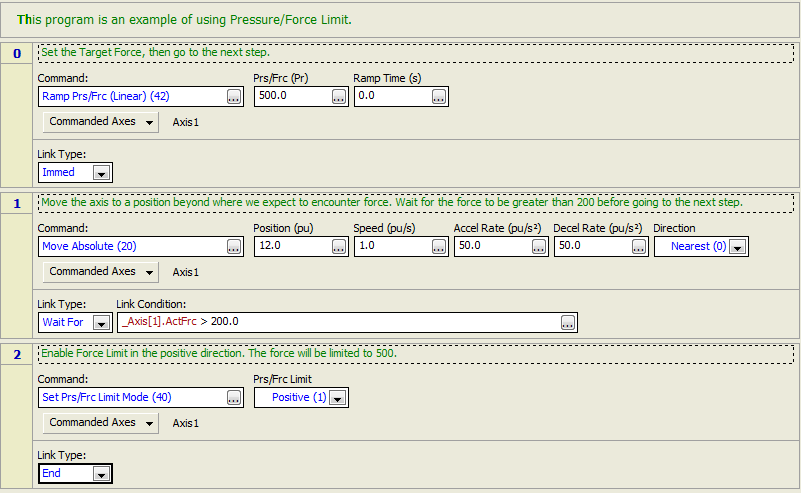

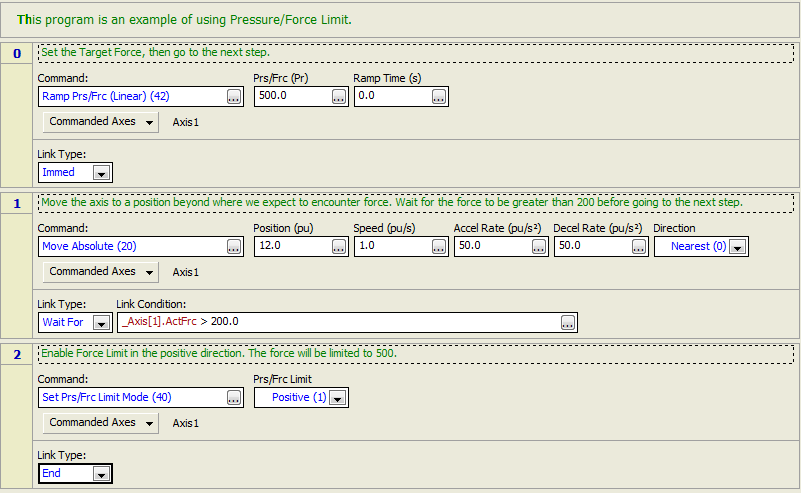

Use a User Program

It is often advantageous to make a User Program to handle the steps above. For example, one step waits until the pressure reaches a certain level, and then goes to the next step that enables pressure limit.

Example:

Changing the Target Pressure/Force

Once the axis is in pressure or force control, you can issue any of the following pressure/force commands to change the pressure/force. For example, you can ramp the pressure up or down, or perform a sinusoidal profile, or follow a spline. For details on each command, see the respective help topics.

DO NOT issue the pressure/force commands that enter pressure/force control, because this will exit pressure/force limit:

For details on control issues to be aware of, see the Pressure/Force Limit Details topic.

Exiting Pressure/Force Limit

An axis will exit pressure/force limit mode if any of the following occurs:

The Set Pressure/Force Limit Mode command is sent with the Pressure/Force Limit command parameter set to 0 (Disabled).

A Direct Output (9) command is sent to the axis.

An Open Loop Halt or Direct Output Halt occurs on the axis.

The Fault Controller (8) command is issued to the RMC.

Switching Between Pressure/Force Limit and Control

Pressure/force limit cannot be used simultaneously with pressure/force control. If the axis is in pressure/force limit, and a command is issued that puts the axis in pressure/force control, the pressure/force limit will no longer be active and the axis will start controlling the pressure or force. However, the Pressure/Force Limit Enabled status bit will still be set, and if the axis exits pressure/force control, it will resume pressure/force limit.

See Also

Pressure/Force Control Overview | Pressure/Force Limit Details

Copyright © 2025 Delta Computer Systems, Inc. dba Delta Motion