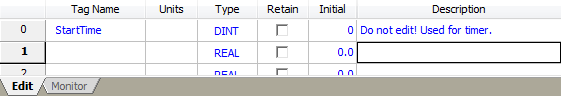

Define a Variable

Define a variable, called StartTime. Define it as a DINT:

Write a User Program

The User Program will consist of the following:

-

Turn off the discrete outputs.

-

Set the StartTime variable to the current value of the _SysMS.

-

Issue the move.

-

Wait until either the axis gets into position, or 5000 milliseconds have passed since the move was issued. Jump to the correct step based on which of these events occurs first. The step that is jumped to will set one of the discrete outputs to indicate whether a time-out occurred or the axis reached position successfully.