Gain scheduling is the process of dynamically changing the gains of an axis based on some scheduling variable. The scheduling variable may be any measurable quantity in any RMC register, such as axis position, pressure, temperature, etc.

For example, an axis may require different gains based on its position. In this case, the axis' position is the scheduling variable. By defining the gains as a function of the axis's position, the gain scheduling results in optimum control.

Gain Scheduling Using Curves

If the axis only needs two different sets of gains, dual gain sets may be used for gain scheduling. This is typically used for systems that change drastically at some well-define point, such as switching from a large valve to a small valve at some point in the travel.

Gain Scheduling Using Curves

Gain scheduling can be implemented in the RMC by using curves and the curve interpolation functions. Gain scheduling involves these steps:

Determine the gain values at several points

Tune the axis for several different values of the scheduling variable. For example, if the scheduling variable is the axis position, you should tune the axis at the ends, and perhaps one or more positions in the middle. Record the gains for each position.

Define the gain curve for each gain

Using the Curve Tool and the gain values you recorded, create a curve for each gain. The scheduling variable will be the x values of the curve, and the gain values will be the y values. The curve interpolates between the points you entered, providing a smooth gain scheduling function. Cubic curves will provide the smoothest transition between gains, although linear curves will work as well. If you choose a cubic curve, choose the Natural Velocity Endpoint Behavior. Constant curves are not recommended, as they will cause undesirable discontinuities in the gain terms, especially the Feed Forwards.

Continually apply the gain to the axis

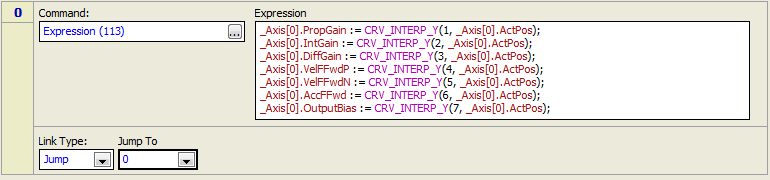

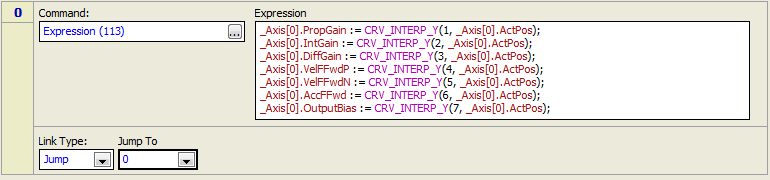

Create a user program that uses the CRV_INTERP_Y function to get the curve values for the current scheduling variable value, and apply the values to the gains. The user program must run continuously.

For example, the user program below will apply the gains and the output bias based on the axis position. The expression can easily be expanded to handle multiple axes.

To successfully use this program, make sure the RMC is in RUN mode. This can be done by setting the RMC to start up in RUN mode in the Programming Properties, on the RUN/PROGRAM page. Also, in the Programming Properties, on the Halts tab, make sure the task this program is running on is set to halt. To start this user program when the RMC starts up in RUN mode, use the _FirstScan tag on the Program Triggers.

See Also

Copyright © 2025 Delta Computer Systems, Inc. dba Delta Motion