|

|

|

DELTA

NEWS - SEPTEMBER 2018

|

|

|

|

|

In This Issue...

News

- Frequency of

Acceleration

- Advanced Training Class -

November

- Underdamped Hydraulic Cylinder Lab

System

- Interns at Delta

- RMC200 PROFINET in

Beta

- A Word About Data Privacy

Distributor

Highlight

People at

Delta

- Paul Huumala – Applications Engineering

& Training

Trade Shows

& Conferences

Learning More

About Delta

|

|

|

|

|

|

How Natural Frequency Limits

Frequency of Acceleration - And Why It Matters

|

The

natural frequency of a

hydraulic system refers to the system’s stiffness.

Systems with higher natural

frequency are

easier to control when accelerating quicker than systems with low

natural

frequency. A hydraulic cylinder can be simply modeled as a mass between

two

springs. Low

natural frequency systems have

a low spring constant relative to the mass of the load.

Conversely, high natural

frequency systems

have a high spring constant relative to the load mass.

So how high should the

natural frequency of

the actuator relative to the frequency of acceleration be? Ideally, the natural

frequency should be at

least four times the required frequency of acceleration. This is true

when

using a standard hydraulic motion controller.

(Hydraulics & Pneumatics, Sept. 24, 2018)

|

|

|

|

|

|

|

Last Chance for Advanced

Training in 2018

Delta's

last Advanced Technical Training class of 2018 will

be offered on November 13, 14, and 15 at our offices in Battle Ground,

Washington. We continue to get overwhelmingly positive feedback about

the

training experience at Delta.

Our

team is constantly making improvements to the

curriculum, presentation, hands-on labs, and trainee experience.

This Advanced Technical Training promises to be no exception.

With

the addition of the Underdamped Hydraulic Cylinder Lab

System (see next article), Delta now has four live hydraulic lab

stations where attendees can tune and program live systems.

In addition to the new Underdamped Hydraulic Cylinder System, there is

the Two Cylinder Press, Basic Hydraulic, and Swing-arm Hydraulic

systems. Students also work with smaller tabletop labs

that focus on PLC/Motion Controller Communications (CompactLogix),

Rotary Motion, and RMCTools User Programming using an

electro-mechanical

actuator.

If you

have already had a Delta Basic Training in some format,

either Live On-Line, Self-Paced, or Classroom, and you want to add to

your RMCTools skill set, consider attending Advanced Training.

Registration information can be found by following the link below.

Classroom

Training

|

|

|

|

|

|

|

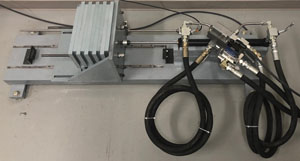

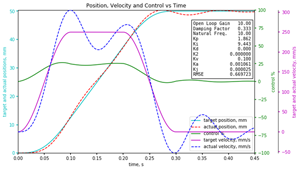

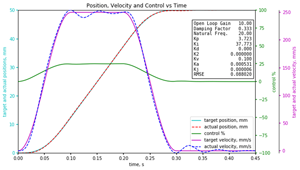

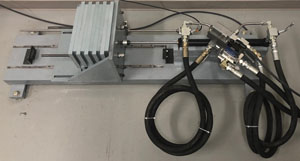

Underdamped Hydraulic Cylinder

Lab System

|

Precise

control is very difficult to achieve on hydraulic

systems that have hose between the valve and cylinder, or use small

diameter cylinders to move heavy loads. This newest lab incorporates

both elements, allowing trainees to experience the challenge of tuning

an underdamped system and to learn how the advanced control

algorithms in Delta’s RMC motion controllers can make it possible.

The system features several

elements that make it

particularly instructive. The cylinder is deliberately undersized for

the designed load and acceleration, and has a longer stroke than

recommended. The load mass can be adjusted by adding or removing steel

plates from the load sled. Finally, the servo hydraulic valve output

can either be routed through short hard pipes or much longer flexible

hoses to either side of the cylinder. By turning a few

ball valves, the dramatic impact of increasing the volume of trapped

oil is easily seen using the RMCTools Plot feature. Trainees can then

use the Tuning Wizard to try to adjust the controller

gains, using First Order and Second Order Tuning algorithms.

|

| |

|

|

|

|

|

|

|

|

|

|

Delta has a long history of

employing interns. In

several cases, these interns have become full-time contributors to the

Delta

team after they graduated. You might have talked with one of

them: David

McNichol, who is an important part of Delta’s Technical Support and

Training

team.

Delta has often been able to

provide these young people with a meaningful and important project. For

example, this summer, an electrical engineering intern designed and

built a prototype thumbwheel pendant for use with our motion

controllers. We are currently doing beta testing and may productize

this

item. We believe it will be valuable for our customers in test stand

applications.

The Underdamped Hydraulic Cylinder lab system in the above

article is another great example. In this case, a talented

mechanical engineering student was able to design and build the system

in a period of 10 weeks. Before he left for his last semester in

college, he gave a demonstration of the system.

These were truly win-win

situations – real-world experience for the interns and progress on

projects for Delta ... plus a chance to

work with some fine young people!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RMC200

PROFINET in Beta Testing

|

|

|

|

Delta

Computer Systems, Inc. is pleased to announce that

PROFINET communications support for the RMC200 is in beta testing.

After beta testing, the RMC200 will be submitted

for certification to the PI organization which standardizes the

PROFIBUS and PROFINET technologies. Pending

certification, the RMC200 will join Delta’s RMC75 and RMC150

controllers as certified PROFINET IO Devices. Delta is

committed to ongoing development and support for a wide variety of

industrial communications protocols, ensuring our customers have the

benefits of

fast, precise servo-hydraulic and servo-electric control.

|

|

| |

|

|

|

|

|

|

|

A Word About Data Privacy

|

There has been a lot of media

attention recently around data privacy

in general, and the new General Data Protection Regulation (GDPR) in

particular. Some companies have sent emails asking people to “re-opt

in” in order to continue to receive newsletters and other emails. But

if you are like us, the last thing you need is yet another email

blast.

Delta has worked hard to build a

reputation

for responsive, knowledgeable technical support. To make this possible,

we need to have contact information for our customers. We do not need

(or want) your personal information – just your business contact

information. Since our products are often in service for (literally)

decades, and our policy is to support our products for as long as there

is demand, we do not have some arbitrary “delete date” for customer

contact information, especially where it concerns technical

support.

Of course, we want to use our

newsletter

mailing list to provide information to you on new products – after all,

marketing and selling is what keeps us in business! We would never give

out or sell this list and you can Unsubscribe at any time in order to

be removed. But we hope you’ll stay! Please contact us if you have any

questions or concerns.

|

|

|

|

|

|

|

|

YCS Co. Ltd

|

|

YCS is an integrating distributor with several brands of complementary high-performance

servo hydraulic controls and equipment. They offer complete solutions packages to industrial

customers on the island of Taiwan.

Testing applications have become a particular area of focus for YCS recently. YCS' technical

staff offers hydraulic system design and controls programming expertise for challenging

applications, well suited to the testing industry. YCS also offers technical services, as

well; for example, YCS engineers recently held a well-received custom Basic RMCTools Training

class at a customer site.

Taiwan's industrial market faces unique challenges and opportunities, with the large Chinese

market located so close. YCS is well-positioned and capable of providing reliable, innovative,

and cost-effective solutions to this dynamic market.

|

|

|

|

|

|

|

|

|

|

|

|

|

Paul

Huumala – Applications Engineering

If you have used Delta's

Technical Support recently, you may

have already spoken to Paul Huumala. Paul has a strong

background

in industrial automation and robotics, as well as mechanical design and

controls programming, which helps him troubleshoot and diagnose

customer problems. In addition to Technical Support, Paul

also is

an active part of the Training team, guiding students through a variety

of topics during Delta's Classroom Trainings.

A native of South Dakota, Paul

and his family enjoy the natural beauty offered by the Pacific

Northwest.

|

| |

| See

Press Release |

|

|

|

|

|

|

|

|

|

|

|

|

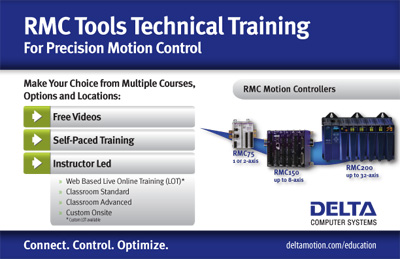

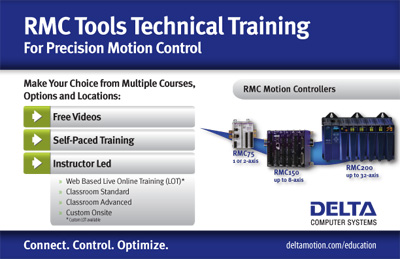

RMCTools Technical

Training

Oct 23 - Oct 24, 2018

RMCWin Technical

Training

Oct 23 - Oct 24, 2018

|

|

RMCTools Technical Training

Nov 6 - Nov 7, 2018

(Battle Ground, WA)

RMCWin Technical

Training -

Oct 3 - Oct 4, 2018 (Battle

Ground, WA)

|

| Sign Up |

Sign Up |

| |

|

|

Delta also provides self-paced

training options, check out some of these options:

Video

Tutorials

An easy way to get up to speed on the RMC's features with easy to

follow video guides.

Online RMCs Try

out the features of RMCTools or custom RMCLink programs when you don't

have an RMC to test with.

|

Nov 13 - Nov 15, 2018

(Battle Ground, WA)

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

Latest RMC Software &

Firmware

(07.31.2018 / V4.08.3)

(07.31.2018 / V4.08.3)

(06.26.2018 / V4.0b)

(06.26.2018 / V4.0b)

(01.11.2016 / V2.31.2b)

(01.11.2016 / V2.31.2b)

|

|

RMC200

CPU

Firmware is V1.07.6 and RMC200 modules (varies) see website RMC200

CPU

Firmware is V1.07.6 and RMC200 modules (varies) see website

RMC75/RMC150 firmware is V3.68.0

|

|

|

|

|

|

|

|

|

|

|

|

|

Upcoming Trade Shows:

Please join us! See

Delta RMC products and talk with our team at the following locations in

2018.

|

|

Portland, OR

October 17-19, 2018

Booth 945

|

|

Georgia

World Congress Center Georgia

World Congress Center

Atlanta, GA

November 6-8, 2018

Booth A1536

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connect with Delta on LinkedIn

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

Watch Delta on YouTubeChannel

|

|

Visit Delta's new YouTube

channel to watch our latest videos.

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

If you are a distributor and

need a password or user ID email us or call Delta at (360)-254-8688.

|

| |

|

|

|

|

|

|

|

|

|

RMC200

CPU

Firmware is V1.07.6 and RMC200 modules (varies) see website

RMC200

CPU

Firmware is V1.07.6 and RMC200 modules (varies) see website