Delta’s Output Filter Improves Force Control Applications

August 19, 2011 – Battle Ground, WA – Delta Computer Systems, Inc. announces the improvement of a significant tuning feature for controlling difficult, dynamic motion control systems. Filtering of inputs and outputs is commonly used to smooth motion. And an Output Filter in challenging motion control applications has proven to resolve problems when low resolution feedback, extreme load variations, poor hydraulic design or valve quality lead to a machine specific problem.

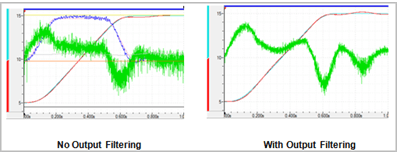

In addition to an Output Filter for position control, Delta motion controllers now provide an Output Filter for Pressure/Force control, including “dual-loop” axes that control position and pressure with the same actuator. Without the Output Filter, designers closing position or force control loops may shy away from using Differential Gain since this gain can cause the Control Output to oscillate leading to poor performance. By using the Output Filter, noise is removed in the Differential gain allowing the Differential gain to be significantly increased. This helps the Actual value to track the Target value of the axis position or force more closely.

Typically, the Output Filter can be set to a value close to the system’s natural frequency. For example, if a system naturally oscillates at 10 Hz, a good starting HZ value for the Output Filter is 10 or higher. This filters out noise that occurs faster than the system can respond, while allowing the controls parameters to apply maximum effect.

Delta’s Output Filter feature improves hydraulic valve applications. The Green lines are the Control Output to the hydraulic valve. Red and Cyan are actual and target values, respectively.

"If a designer runs into a design barrier the Output Filter can become a powerful tool helping make tuning easier and motion more stable." stated Peter Nachtwey, Delta’s President. "And when retrofitting a machine, making use of an Output Filter for position or force control loops may be the only or best practical choice." Nachtwey added.

The high performance motion control products that Delta designs, manufactures and markets are used worldwide for hydraulic, pneumatic and electric closed-loop control in a wide array of single and multi-axis applications, including testing, food, energy, automotive, entertainment, plastics, materials, aerospace, metals, forest products and others.

###

About Delta: For over 40 years, Delta has supplied motion controllers and other industrial products that enable better performing machines. Delta's RMC Motion Controllers are used for hydraulic, pneumatic, and electric closed-loop control in a wide array of single and multi-axis control and testing applications. For more information contact Delta Computer Systems, Inc., at (360) 254-8688, email technicalsales@deltamotion.com, or visit www.deltamotion.com.